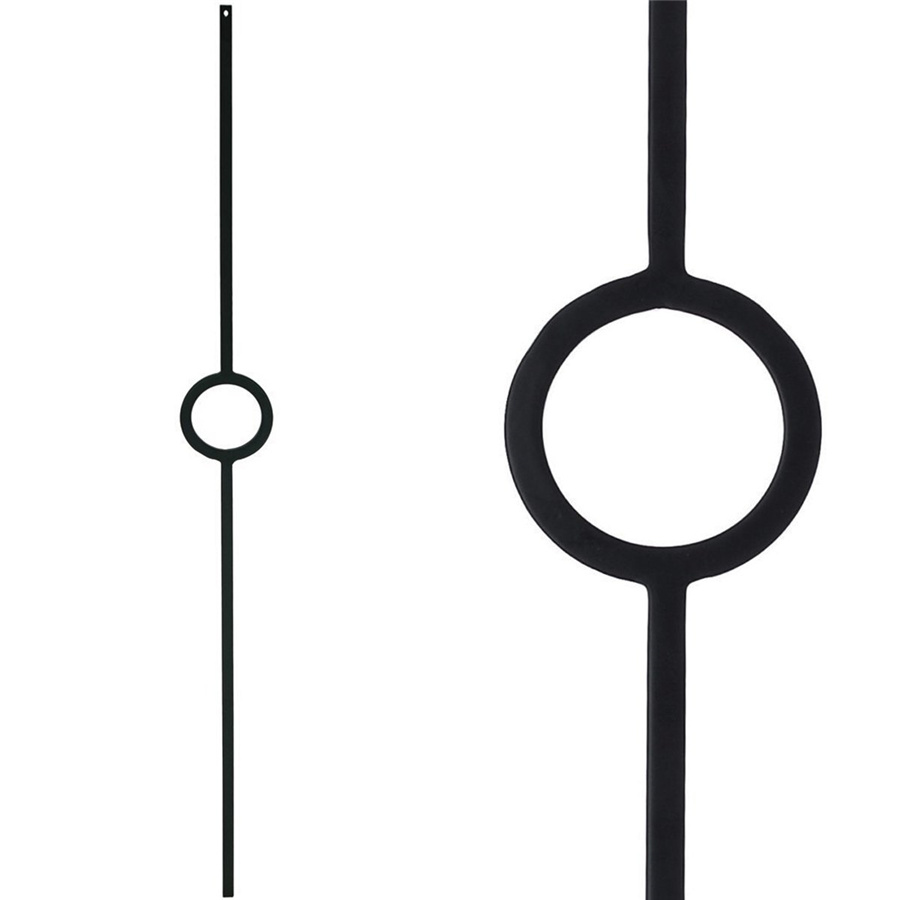

China Best Forge Iron Balusters Company Factories - Single Circle/Ring Wrought Iron Balusters/Spindles – Primewerks

China Best Forge Iron Balusters Company Factories - Single Circle/Ring Wrought Iron Balusters/Spindles – Primewerks Detail:

To easy for installation, which is doweled top, and the balusters/Spindles can be cut to length by trimming bottom of the baluster/Spindle with metal cutting tool. And in view of the cost savings, ease of trimming and over all the ease of handing, most of buyer have made the switch to the hollow Balusters/Spindles instead of solid ones.

Friendly reminder, usually the iron balusters/Spindles must pass the 4 inches spacing rule, meant that a 4 inches sphere cannot pass through any portion of the balustrade/Spindle. Meanwhile, if you can’t find any products you are looking for, and need additional assistance or any question you have, then please do not hesitate to contact us via phone or e-mail us alan.chen@primewerks.com.cn , we are glad if anything we can do for you on stair products.

What Is the Discrepancy between Solid and Hollow Iron Balusters (Or Spindles)?

Although they are similar in strength, durability, and design capabilities, both solid and hollow iron balusters/spindles have their own unique benefits. And how to know which one is right choice for you? Here are a few things to consider when you will make your final decision.

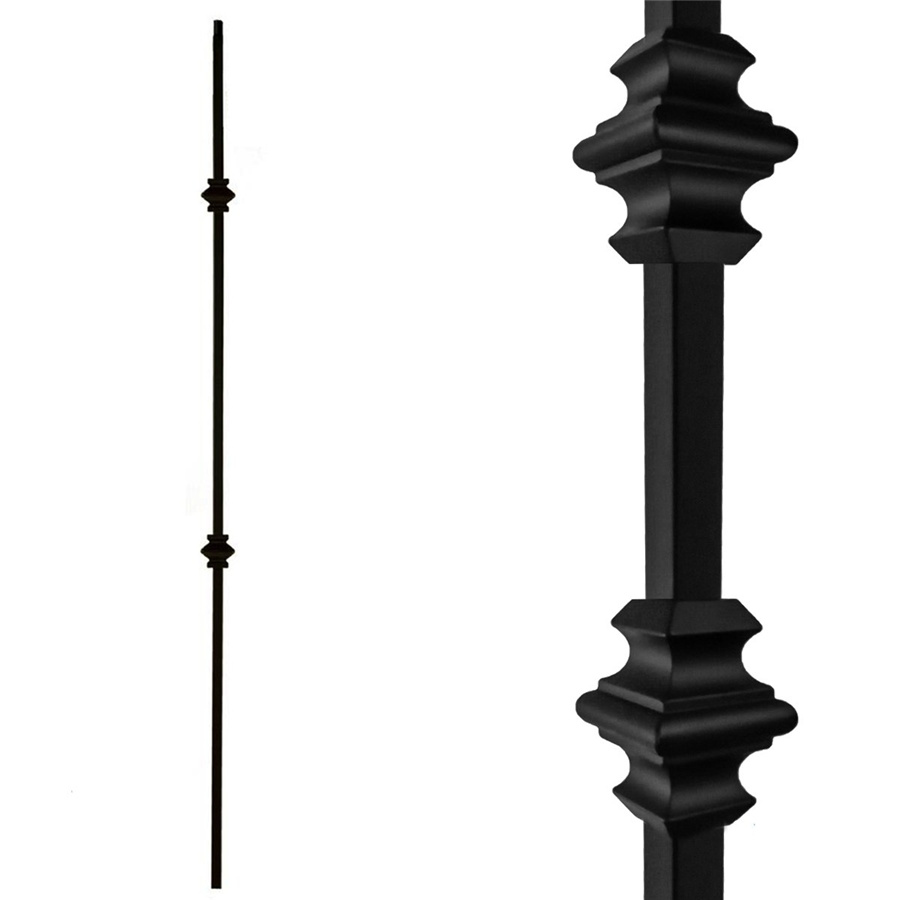

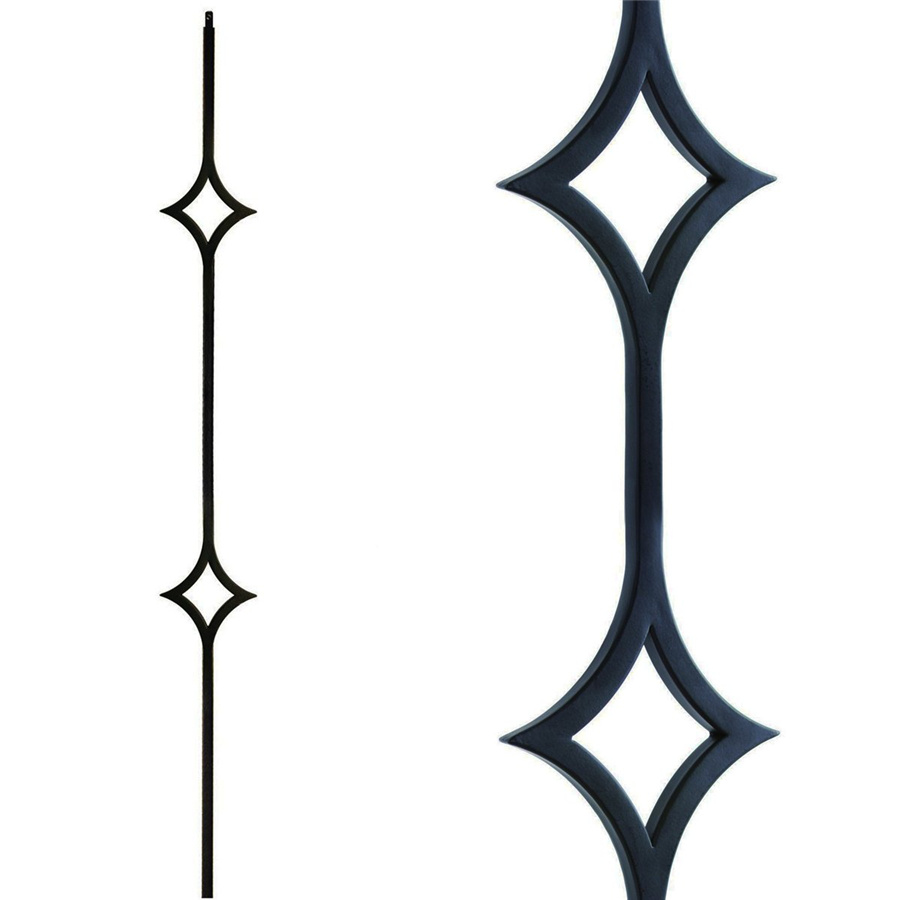

Solid iron balusters/spindles are made of wrought iron, a tough, forgeable form of iron that can be rolled and manipulated into different shapes. This process results in a lightly textured surface, giving these iron balusters an “Old-World” look. And because artisans can shape the metal more freely, solid iron balusters/spindles tend to be more intricate in design.

Regarding hollow iron balusters/spindles, high-quality iron is poured and shaped through a casting process. This results in a smooth, refined finish. In view of the constraints of mold casting, the design options are often much simpler in form, but still popular for many modern homes.

Strength and Durability. As you may have guessed, solid iron balusters/spindles are heavier than their hollow version. Hollow iron balusters/spindle also have a bit more give than solid balusters, but this flexibility doesn’t significantly impact the durability of the system once installed on the stairway. Both options are strong and reliable for long-term use as they are completely adequate and meet stair code compliance.

Cost Concern. Solid iron balusters are generally more expensive than hollow balusters, because they are made of more iron material and require intricate shaping. With hollow balusters, you also have the opportunity to save on shipping costs. They weigh less than solid balusters, which usually means lower shipping and handling charges, as well as better for the environment.

Installation. Iron balusters/spindles, both solid and hollow will arrive oversized and must be cut down on-site to fit your stairway accordingly. Hollow iron balusters/spindles are easier to install, because there is less material to cut through – a small power tool or hand tool will do the job. Solid iron balusters require more time and powerful machinery to cut to size. Aside from cutting, the rest of the installation process is very similar for both styles.

Versatility. Solid Iron Balusters/Spindles are suitable for both interior and exterior use. Hollow Balusters/Spindles are not generally considered suitable for exterior use unless they are welded to the top of iron baluster/spindle and the bottom of hand rails. This is because without a welded “seal” moisture can accumulate inside the baluster and cause them to rust from the inside out.

If you are using iron balusters on an exterior railing system with non-metal or non-welded top and bottom rails, then we strongly recommend you use the solid iron balusters/spindles.

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our company for the long-term to develop together with customers for mutual reciprocity and mutual benefit for China Best Forge Iron Balusters Company Factories - Single Circle/Ring Wrought Iron Balusters/Spindles – Primewerks , The product will supply to all over the world, such as: Serbia, Durban, New Orleans, Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our products and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.